NIPPON KINZOKU CO., LTD. (Headquarters: Minato-ku, Tokyo) will strengthen sales of its environmentally friendly product, L-DieL (Long Die Life) finish stainless steel, which reduces die wear. L-DieL Finish modifies (softens) the passive oxide film on the surface of stainless steel, thereby reducing die wear during pressing operations and contributing to improved productivity and cost savings for our customers.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250716360497/en/

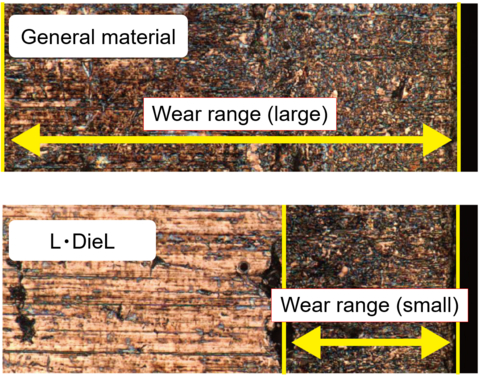

Difference in Wear Range between L-DieL Finish and General Materials *Base material: SUS304, 1/2H, 0.1mm, Clearance: 5µm, Stroke: 600spm

The passive oxide film that maintains the corrosion resistance of stainless steel is mainly composed of chromium oxide and is extremely hard. Although the film thickness is only about 10 nanometers, it has a detrimental effect (accelerated wear) on press dies that come into repeated contact. To soften this film and reduce die wear, we have developed the L-DieL finish as a surface treatment.

We have certified our L-DieL finish as an “Eco-Product,” which improves productivity and reduces costs for our customers. Our goal is to achieve net zero CO₂ emissions by 2050, and we are committed to sustainable manufacturing through the widespread use of environmentally friendly materials.

Additionally, this product aligns with our 11th management plan, "NIPPON KINZOKU 2030," and is a unique product that meets customer needs based on the "Near Net Performance" keyword (achieving the required performance of the final product with the material).

Features of L-DieL Finish

- Reducing die wear during press processing, expected to extend die life.

- Compatible with most stainless steels, including SUS304, SUS430, and various surface finishes.

- Chemical composition and mechanical properties comply with JIS standards.

- Appearance and corrosion resistance are equivalent to those of general-purpose stainless steel.

L-DieL Finish Structure

Our unique surface treatment technology softens the passive oxide film. This reduces die wear and decreases the frequency of maintenance.

https://www.nipponkinzoku.co.jp/assets/images/2025/03/l-diel_en_main-620x350-1.jpg

Manufacturing Range

Steel Types: SUS304, SUS430, etc.

Finish: Spring, BA

Thickness [mm]: 0.08–0.50

Width [mm]: 600 or less

Click here for more details.

https://www.nipponkinzoku.co.jp/assets/images/2025/07/525b3b21fd450afefd516123f0400db3.pdf

About NIPPON KINZOKU Group

Our products have been used in a range of areas from the precision field to the construction industry. https://www.nipponkinzoku.co.jp/en/

View source version on businesswire.com: https://www.businesswire.com/news/home/20250716360497/en/

© Business Wire, Inc.

Disclaimer :

This press release is not a document produced by AFP. AFP shall not bear responsibility for its content. In case you have any questions about this press release, please refer to the contact person/entity mentioned in the text of the press release.